This is a simple-to-construct model that can be used for sport or competition flying

By Jean Pailet

Photos courtesy the author

As seen in the February 2004 Model Aviation.

The Arm Soar is an old Free Flight (FF) Hand-Launched Glider (HLG) that is still being flown competitively, with occasional success, by a really old man (I’m in my 70s now!).

My younger son, Barry, originated the model’s design just before the 1975 Nationals (Nats) in Lake Charles, Louisiana, when, in his enthusiastic haste, he carved and installed the wing backward on the Flash HLG that he was readying for our trip south. The tried-and-true Flash, by “Fast Richard” Mathis, has swept-forward outer-panel trailing edges (TEs) and a straight leading edge (LE) on the wing.

Barry ended up with swept-back LEs and a straight TE on his model. To this day, he claims that it was an intentional design innovation! Since he placed with “his design” at that Nats, who am I to dispute him? Regardless, we’ve been improving the design ever since.

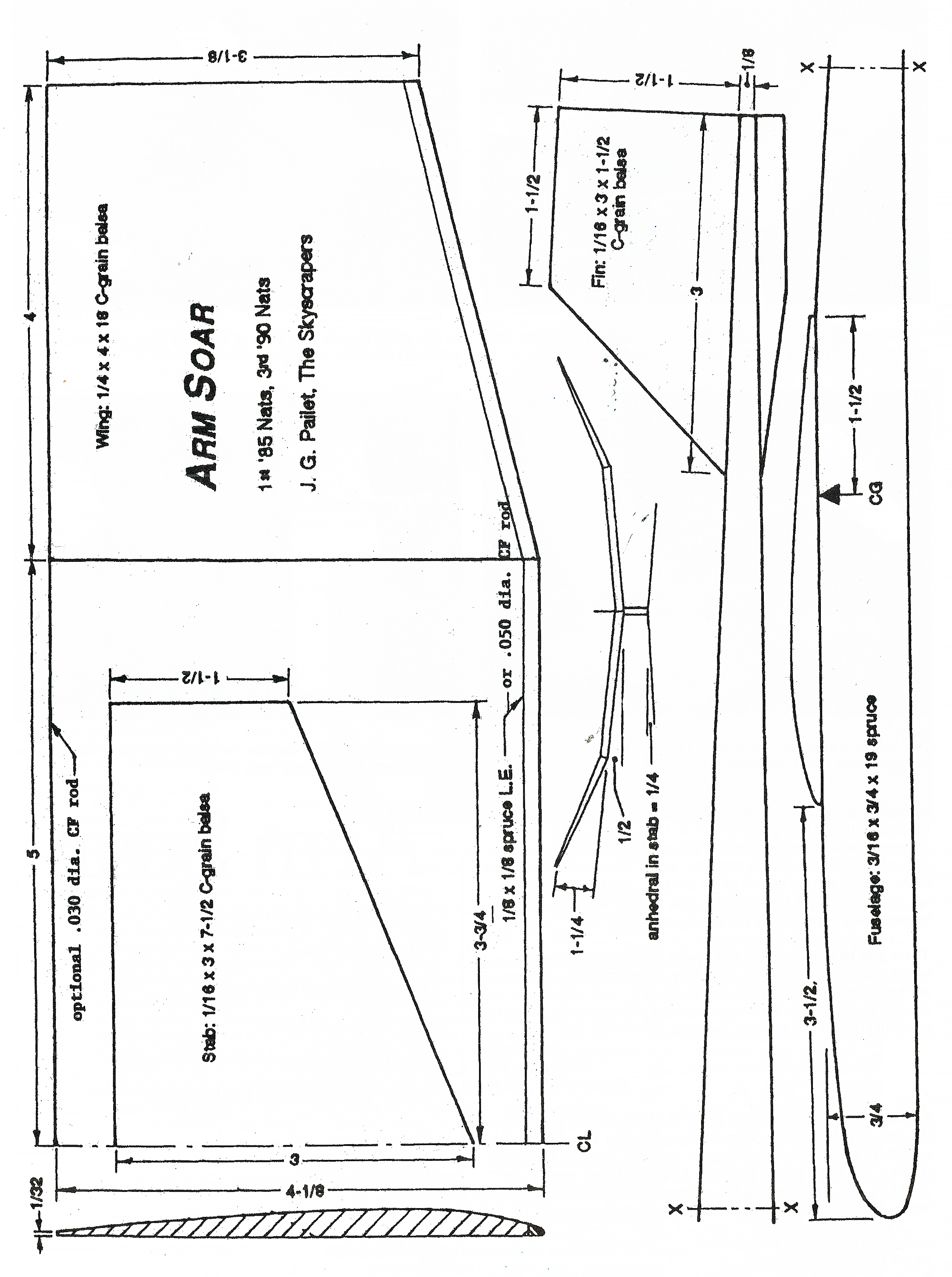

The evolution resulting in the Arm Soar shown on the accompanying drawing has involved many changes; all that remains of the Flash is the still-apparent similarity in wing and tail-surface shapes.

Among the differences are increased wing and stabilizer spans and areas, decreased fuselage length with a shortened nose, a new wing airfoil with a rounded hardwood or carbon-fiber (CF)-rod LE, and a symmetrical airfoil on the horizontal tail.

Beginning with Barry’s success at the 1975 Nats, the Arm Soar has accumulated a noteworthy contest record that includes first place in Open HLG at the 1985 Nats. That victory was a contributing factor in our New York team (Danny Agers, John Carbone, and me) winning the then-popular HLG Perpetual Team Trophy that year. At the 1990 Nats, the model placed third in Open HLG.

Between those contests the Arm Soar placed well at most of the major Northeastern FF meets, including the various Eastern Championships held at Galeville and Johnsville, New York. It has continued to perform well despite the ever-increasing age of the sore arm upon which it is so dependent.

Construction

Constructing the Arm Soar is easy and should be essentially self-explanatory with the accompanying full-size drawing. However, I need to call your attention to some of the details.

As I’ve noted, the stabilizer should have a symmetrical airfoil and it uses the same V of anhedral as its ancestor the Flash.

The drawing shows a 1⁄8 hardwood LE on the wing, which is a great asset in durability. However, since modern carbon-fiber materials are so readily available, now I use .050-inch-diameter carbon-fiber rod for the wing LE and .030-inch rod for the TE. Burying the LE rod slightly in the balsa and then carving the airfoil to mate with it automatically provides the desired LE rounded contour.

Carve the overall airfoil using a template of the shape shown on the plans. The wing’s inner panels are a constant thickness while the outer panels taper to 1⁄16 inch at the tips (resulting in a flat “airfoil” at the wingtips). Using the .030 carbon-fiber rod at the TE provides a consistent thickness and strength.

The fin has a symmetrical airfoil. I generally use a 1⁄4-inch-thick, wedge-shaped finger rest at the wing/fuselage intersection to help beef up that critical joint. Gluing a couple of sandpaper finger “grips” to the fuselage at comfortable locations improves the glider’s launchability. The fuselage can be hardwood or extremely hard balsa.

The center of gravity location is shown on the plans. My dethermalizer (DT) preference is a swinging weight attached approximately halfway between the wing and the stabilizer. Since it is necessary to add nose ballast to balance a glider, the swinging weight ballast/DT performs a dual function with no unnecessary added weight.

Trimming: The trimming process is conventional. Since I am righthanded, I launch the Arm Soar to the right and trim it to glide to the left. Glide turn is achieved with varying combinations of stabilizer tilt, rudder, and slight differential elevator (up—left/down—right). This “tail twist” helps in the transition from launch phase to glide. You can counteract any tendency to spin in during the glide by warping down the inboard wing’s (preferably the inner panel only) TE.

There you have it: An HLG that can be competitive without a world-class athlete doing the launching. The Arm Soar’s primary attribute is that it has done so well flown by a weak-armed nonathlete. As long as I have this model, I refuse to retire solely to Catapult Glider as so many of my peers have done!

Sources: The only specialized material (if you choose to use it) in the Arm Soar is the carbon-fiber rod for the wing LEs and TEs. Carbon-fiber rod is .020 inch in diameter and larger.

Comments

Add new comment