Written by Chris Mulcahy

As seen in the August 2015 issue of Model Aviation.

Stifling Static

This month I welcome back David Buxton who has some interesting information about the static electricity generated by our helicopters. Here’s what he shared: Many of our helicopters use a tail belt drive system that is similar to a high-voltage Van de Graaff generator, which also uses end pulleys and a belt. Triboelectric tables predict how much static will be generated, depending on the two materials involved. The best triboelectric table that I have found is listed in “Sources.”Tailboom Static

A helicopter’s metal or carbon-fiber tailboom is where the static builds, much as it does on the dome of a Van de Graaff generator. Most RC pilots who have belt-driven tail systems don’t experience static electricity problems. If the belt materials and pulleys are carefully selected to be close together on the triboelectric table, then a minimal amount of static will build. Search the Internet for articles about what to do if your Van de Graaff generator quits working and you will find that these generators can be easily defeated, perhaps because of oily dirt on the belt, lint, sharp bits of wire on the dome, or humidity. Nitro heli exhaust will lubricate the belt, which is a good thing.Image

Diagram 1

Torque Tube

Many of our helicopters use a torque tube, which can be fragile for beginners and for those who often land their helicopters on rough terrain, thick grass, or weeds. A belt system is mechanically more robust and might be your best choice as long as static electricity problems can be eliminated. In a dust storm, full-scale helicopters generate spectacular amounts of static from their main rotors and tail blades. Spinning tail blades generate static, even if dust is not blowing. Gears, including main gear against pinion and torque tube gears, generate some static. A torque tube does not entirely eliminate helicopter static, especially when the air is dry. A torque tube contributes vibration, which can affect gyro performance.Symptoms

Radio restarts (because the radio’s power supply is spiking too low, for example) tend to result in the receiver ignoring the transmitter until the restart is complete. Static electricity can cause abrupt, surprise behaviors and servo twitching. Static problems can also cause radio restarts.More Physics

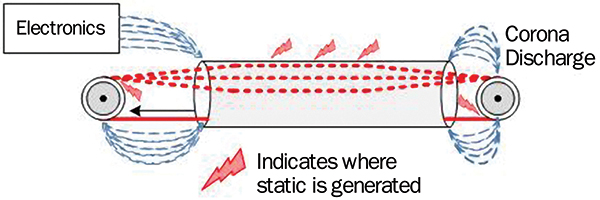

The physics of a Van de Graaff-style high-voltage generator act like a constant current source. A steady current flow into a capacitor (such as the Van de Graaff dome and tailboom) results in the voltage steadily ramping up. The most common limits to increasing voltage are sparks, corona discharge, and dissipative leakage paths (humid air and static dissipative products). Electronically noisy sparks and corona discharge are what put your electronics at risk. The lightning bolts shown in Diagram 2 indicate where the static electric currents are generated, rather than radiated. The blue lines indicate where corona discharge generally takes place.Image

Diagram 2

Slack Tail Belt

The tail rotor puts a lot of load on the belt, which causes it to stretch. The opposite side of the belt goes slack and slaps against the inside of the tailboom. This will especially be a problem when performing aggressive pirouette maneuvers.Image

Diagram 3

Greasy Belt

The most important thing that a heli pilot can do is keep the tail belt well lubricated, which does an excellent job of nulling the triboelectric effect. Grease against grease has no triboelectric difference. Lubricate all four surfaces of the belt. Experiments indicate that a good lubricant is more effective than graphite products selected for conductivity. Another benefit of a lubricated belt is that it lasts much longer compared to a dry belt. For instance, a dry belt will try to climb the side walls of the pulley, resulting in most of the wear and tear that often leads to loose strands of belt material. Use a dry silicon lubricant if you fly where dust is a problem. If you don’t like cleaning up the grease that gets thrown off the belt, reapply it. Lubricating the gears is also recommended for reduced static noise, quieter performance, and extended life. Note that some lubricants, such as WD-40, are reported to be hostile to belt and pulley materials. Petroleum distillates are also a problem. Select the proper lubricant and be aware that propellants can be problematic.Heli Ground: Tie It Together

Diagram 4 illustrates where the triboelectric effect generates static if the two separating surfaces are not lubricated. A carbon-fiber frame will accomplish most of the illustrated connectivity without the need for wires.Image

Diagram 4

The most important connection is between the tailboom and the frame (tailbooms are typically clamped in plastic). It is almost as important to connect the metal components of the tail assembly to the tailboom (a metal tail case would be an ideal solution). You can daisy chain the wiring because there is no need for a single-point approach. Dissipative or conductive interconnecting of all the conductive parts is recommended, even if your heli uses a torque tube. Static can be effectively dissipated with 10 million ohms—even as much as 100 million ohms because of humidity or static dissipative products. There’s no need to sand off any paint unless you plan to use a multimeter to check wiring continuity. If you have lubricated the belt and established a good helicopter ground system, you may not need to apply more treatments. If your heli flies in dry air, you want minimal corona noise for better long-range performance, or if you simply want to do what is best for your helicopter’s flybarless and radio system, then the following will be of interest to you.

Connecting Radio Ground to Heli Ground

I have discussed the problem of connecting heli ground to radio ground with several electronics engineers who design high-voltage probes for oscilloscopes. Electronics engineers frequently deal with analog ground that must be kept quiet and must connect with noisy digital and/or high-voltage circuits. After reviewing helicopter ground and radio ground, I posed the following: Imagine a Van de Graaff machine and a radio nearby on an insulated stand. What would you do for best radio performance? The answer is to connect a wire between the dome and the radio’s ground. This solution is recommended because the corona frequencies are well below 2.4 GHz. For helicopters, if you are concerned about high-fault currents from the battery or a defective motor, use a resistor in parallel with a capacitor. A resistor limits the maximum fault current. The capacitor provides an effective short circuit at corona frequencies. We want the radio system to dance up and down with the helicopter.Image

Diagram 5

There are alternatives to using a resistor and capacitor in parallel when making the connection: • Connecting to a battery negative would be less risky. • Use a 2-amp fuse and check it occasionally to be sure it has not blown. • Use a resistor and skip the capacitor; it’s better than no connection.

Comments

Add new comment